Product

Your location: Home>Product>Geosynthetics>EPDM waterproof roll

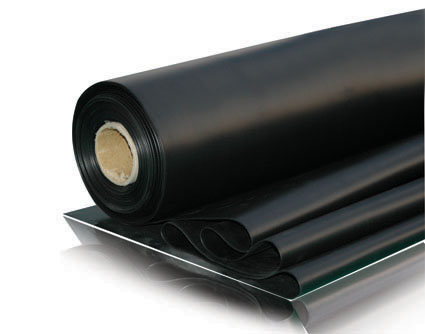

EPDM waterproof roll

Spec:

Brand:

Scope:

Molecular 300 million propylene rubber waterproof roll is recognized as one of the most excellent high elastic waterproof materials in the world. It is the most commonly used waterproof material in the world and one of the new chemical building materials that the Ministry of construction focuses on. "Wanhua" brand EPDM waterproof roll adopts the most advanced continuous extrusion vulcanization to one-body production equipment and process in the world, which is controlled by computer and has stable process. Strict material selection, advanced formula, production organized according to ISO9001 quality system, the whole production process is always under control, to ensure the high performance and quality of the product, so that the "Wanhua" waterproof roll has better compactness, no bubbles, no vertical and horizontal performance differences. The product performance has reached or exceeded gb18173.1-2000 standard, and has reached the advanced level of similar products abroad.

EPDM waterproof roll is characterized by single-layer construction, cold operation, light weight, aging resistance, long service life, high tensile strength, large elongation, strong adaptability to base shrinkage and cracking deformation, wide range of use (- 40 ° C to 100 ° C), excellent waterproof performance, and service life of up to 50 years, which is known as the "king of waterproof".

Scope of application

Waterproofing and moisture insulation of various industrial and civil buildings, bridges and culverts, tunnels, dams, reservoirs and other construction projects as well as various underground projects.

Storage, transportation and storage of waterproof roll and supporting adhesive shall be stored in a cool, ventilated and dry warehouse and away from heat source. The adhesive contains organic solvent, which is inflammable. Attention shall be paid to fire prevention during use, storage and transportation. The storage period of the matching adhesive is one year, and it can be used after passing the inspection in the later stage.

Brief introduction of construction

1. The base course shall be flat, dry and clean, and shall be free of crisp, sanding and peeling.

2. Before construction, the base course shall be cleaned and foreign matters shall be removed.

3. Spread the waterproof roll on the base completely to relax the stress of the sheet. Apply the base adhesive to the surface of base course and sheet according to the amount. When the adhesive is basically non stick, pave and compact it.

4. When paving the second roll of coiled material, the overlapping edge of the first roll shall be protruded by 100mm, and the base adhesive shall not be applied. The sheet shall be paved on the base according to the requirements of 3, so as to complete the whole laying work. When laying, it is not allowed to tighten the waterproof roll with great force.

5. After the base course is paved and pasted, the lap joint shall be wiped with special solvent, and then the sheet lap adhesive shall be applied on both sides of the joint after it is fully dry. After the adhesive is fully dry, it shall be applied for the second time. After the adhesive is dry to the point where it does not stick, it shall be flattened and compacted with roller.

6. Pay attention to fire prevention during construction. Good ventilation facilities shall be provided at the site of basement airtight construction I before construction.

Main technical indexes of products: gb18173 standard (jisa6008 is equivalent to this standard)

Prev:EPDM waterproof roll

Next:PVC waterproof roll

Time:2019-11-15 11:16:30

HOME

HOME

PHONE

PHONE

SMS

SMS