Product

Your location: Home>Product>Polymer waterproof coil>PVC waterproof coil

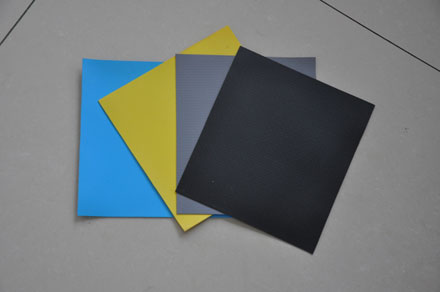

PVC waterproof coil

Spec:

Brand:

Scope:

Product characteristics

Polyvinyl chloride (PVC) waterproofing membrane is a high quality, high polymer waterproof sheet with excellent properties. Through the addition of plasticizer, UV resistant agent, anti-aging agent, stabilizer and other processing aids, the polymer waterproofing membrane produced by extrusion method is produced by PVC resin. The product has the advantages of high tensile strength, high elongation, good stability, low shrinkage, good flexibility at low temperature, good aging resistance, high penetration resistance and long service life. It is recommended by the Ministry of construction, especially its wide width of 2.05 meters, thereby reducing the hidden danger of many joints for the waterproof layer. The thermoplastic properties of polychlorinated 2 ene give the coil hot air welding and alert and fixed nature. It can completely solve the problem of leakage caused by poor glue performance in the construction field. The product is 1.05M wide, 2.05m wide, 2.1m thick, 0.8, 1.0, 12, 1.5, 2.0mm thick, with standard length of 2.0m (special specifications can be customized), with reliable product quality and convenient construction. Due to the unique product formula, the service life of the product is far beyond the ordinary waterproof materials. The service life of the whole waterproof system is long. The roof is more than 30 years, and the underground is more than 50 years. It is widely used in the construction and civil engineering.

Main points of construction

1. Long service life, aging resistance, roof materials can be used for more than 30 years, underground for up to 50 years.

2. High tensile strength, high elongation and small change of heat treatment size.

3. Good flexibility at low temperature, good adaptability to environmental temperature change.

4. Good root system permeability resistance, can be made into planting roof.

5. Good perforation resistance and impact resistance.

6. The construction is convenient, the width and width overlap are few, the passenger welding is firm and reliable, and there is no pollution.

7. Strong chemical resistance, suitable for special occasions.

8. It has good plasticity and convenient corner details processing.

9. Convenient maintenance and low cost.

10. The light color of the surface reflects ultraviolet radiation, and the heat on the west end of the coil surface is less and the temperature is low.

11. The coiled material has good water vapor diffusion, the condensate is easy to be discharged, and the moisture and moisture left to the base layer are easy to be discharged.

Product classification

N1.. non exposed waterproof material without composite layer. (mainly used for the detailed treatment of non exposed waterproof)

N2.. no composite layer exposed waterproof material. (mainly used for detailed treatment of exposed roof waterproof)

L1. Fiber single-sided composite non exposed waterproof material. (mainly used for large-scale use of non exposed waterproof layer)

L2.. fiber single-sided composite exposed waterproof material. (the housing shall be used for the large-scale use of the exposed roof waterproof layer)

W1. Reinforced non exposed waterproof material inside the fabric. (mainly used for non exposed waterproof layer)

W2. Reinforced and exposed waterproof material inside the fabric. (mainly used for Z water proof of exposed roof)

Due to the unique product formula, the service life of PVC waterproof roll is far longer than that of ordinary waterproof material and the roll is excellent

It can be widely used in various fields of waterproof.

(1) it is applicable to roof waterproofing of industrial and civil buildings, including planting roof, flat roof and sloping roof.

(2) underground waterproofing of buildings: including waterproofing of reservoirs, dikes, pools, canals and basement.

(3) tunnel, grain depot, civil air defense project, landfill, artificial lake waterproof, etc.

Man-made Lake

Steel structure roof

Upper roof

Basement

Planted roof

Tunnel

System plan

Sticky system

It is generally used for the side wall of roof and basement. Use special adhesive to bond the composite non-woven PVC with the base (concrete surface, metal surface, wood surface) firmly.

The non-woven fabric under PVC can play the role of isolation, protection and buffer. Requirements for base course: moisture content ≤ 8%, flat and dense, no peeling, etc., and the construction is greatly affected by the weather

Mechanical fixing system

Generally, it is used in roof engineering to carry out pull-out test on base course. According to pull-out value, wind load and dynamic wind load simulation test value and empirical formula provided by the company, the spacing and quantity of fixed parts are calculated to meet the requirements of wind resistance. The fixed parts are self drilling self tapping screws and special metal gaskets. Construction is less affected by weather and temperature.

PVC gasket fixing system

It is generally used for side wall of basement, railway and highway tunnel, side wall and vault. The requirement of base Flatness: 1 / 8-1 / 6 (high loss ratio). This method is not subject to base temperature

Under the influence of humidity, construction can be carried out even if there is water seepage on the surface of the base course.

Empty paving system

Generally used in underground, roof, floor, roof garden and pedestrian roof. No adhesives and fixings. According to the needs of users, a layer of non-woven fabric is added to the waterproof layer as the protective layer.

In order to obtain the best performance of waterproof system for some special parts, the accessories approved by the system shall be used and implemented in accordance with the national standards and specifications

System accessories

Whether the waterproof system can show excellent performance is affected by many factors, among which product material and construction quality are the main factors. Accessories Department of waterproof system

It also has a great impact on the service life of the system. After strict evaluation, testing and tracking, Shenghai company selects accessories with long-lasting and stable quality to ensure the complete embodiment of the system function.

Performance index of PVC waterproof roll (GB12952-2003)

Characteristic

1. High strength, puncture resistance and tear resistance:

2. Cold construction, weldable, mechanically fixed, welding temperature to be strictly controlled, high technical requirements;

3. It is not soft enough to be used on complex and irregular base;

4. The heat shrinkage and the later shrinkage are both large;

5. The ability of ultraviolet aging resistance is poor. With the migration of plasticizer, the coiled material gradually becomes hard and brittle;

6. It is suitable for waterproofing of underground works (the base course is relatively flat).

Application method of PVC waterproof roll I

Combined with the characteristics of PVC coil, the cold bonding method, air laying method and mechanical fixation method are generally used, and the unique hot air welding process is also provided. The complex waterproof construction parts shall be provided with special supporting facilities. PVC special accessories combination construction

Cold sticking method

Using the special adhesive for PVC coil to paste the coil on the base by cold operation is called cold adhesion method. According to different waterproof design requirements, cold bonding can be divided into full bonding or partial bonding.

I. the full adhesion method is the application method of fully bonding PVC coil on the base.

1) during construction, pre laying shall be carried out first. PVC coiled material shall be naturally laid on the base surface of setting out (not bonded at first), which shall be smooth and straight without distortion.

2) the longitudinal lap width of the coil shall be 50mm, and appropriate cutting shall be carried out. Butt joint treatment shall be adopted in the transverse direction, on which 200 ~ 250mm wide non composite layer (class n) shall be used. PVC coil is covered, lapped and welded.

3) fold the long side of one or more coils in half (about 10m), and apply special adhesive on the base layer and the coil surface respectively from the folding position. When the adhesive is dry to non stick, compact the pre laid coil surface with the press roll for closing and pasting. Then fold up the other parts that are not folded, continue to operate from the folding place as mentioned before, and then paste firmly and compact by analogy. Finally, the seam welding construction is carried out.

2. Paste the coiled material locally. When the PVC roll is paved, the roll and the base layer are pasted on the base layer by point or strip sticking method.

Spot Adhesion: Spot Adhesion between coiled material and base. No less than 5 points shall be bonded per square meter, and the area of each point shall be 100mmx100mm.

Strip bonding: strip bonding between coiled material and base course. The bonding surface between each sheet of coiled material and the base course shall be no less than two, and the width of each sheet shall be no less than 150 mm.

Empty paving method

That is to say, when the PVC waterproof roll is laid, the roll and the base layer are only bonded within a certain width around the whole waterproof layer; the construction method of the rest parts are not bonded. The construction process of air paving method is as follows:

Base leveling and cleaning - snapping line - roll pre laying roll joint lap welding special parts processing and fixing, edge sealing material acceptance.

First, the coil shall be pre laid according to the full adhesion method, and the longitudinal lap width shall be 50mm. For its deception, the coiled material around the whole waterproof project shall be fully adhered and the lap joint shall be welded. Butt joint treatment is adopted in the transverse direction, on which 200 ~ 250mm wide PVC coil without composite layer (class n) is used for covering, lapping and welding.

Mechanical fixation

That is to say, the construction method of mechanically fastening the fixed parts to connect the coiled material and the base course.

(1) during the construction, the pre laying shall be carried out first, and the full adhesion method can be referred to. The longitudinal lap width is 100 mm, with a period of 50 mm for fixings, which need to pass through the insulation layer and be fixed on the structural layer.

(2) fixed spacing according to design and calculation. Use the impact drill to drill holes first, and the hole diameter is slightly smaller than the outer diameter of the fixed screw. Fix the fixings in place and tighten them with electric screwdriver. After that, cycle operation in turn. Each lap joint shall be welded, and butt joint treatment shall be adopted in the transverse direction, and 200 ~ 2500mm wide non composite layer (class n) coiled material shall be used to cover the lap joint for welding.

Prev:Reinforced PVC waterproof coil

Next:Polyethylene polyester composite waterproof roll

Time:2019-11-15 14:47:24

HOME

HOME

PHONE

PHONE

SMS

SMS